| 12 Sept. | 11:30 - 13:00 | |||

|

|||||||

| ADDITIVE & 3D MANUFACTURING | |||||||

| TT.VI - Technical Multi-Track with Parallel SYMPOSIA | |||||||

| Advances in Additive Manufacturing of Metal Alloys | |||||||

| Co-organized with ENEA Chairs: Giovanni DI GIROLAMO & Daniele MIRABILE GATTIA, ENEA and Giuseppe BARBIERI, ENEA-CALEF |

|||||||

| Sponsorized By: Programma Operativo Nazionale Ricerca e Innovazione 2014-2020 e Fondo per lo Sviluppo e la Coesione | |||||||

|

|||||||

|

Metal additive manufacturing (AM) is constantly growing over the recent years and can be considered competitive with traditional manufacturing processes, for applications in various sectors (automotive, aerospace and energy), characterized by low production volumes, high level of customization and complex geometries. From new AM technologies, to newly developed alloys with improved processability, the need to clarify the link between microstructure and final properties is of paramount importance to unlock the full potential of metal AM. |

|||||||

| TT.VI.A.1 | Daniele MIRABILE GATTIA - CV ENEA Metal additive manufacturing for sustainable energy applications |

|

|||||

| TT.VI.A.2 | Barbara PREVITALI - CV Polytechnic University of Milan Spatial Beam Shaping in Laser Powder Bed Fusion for enhancing the Processability of E-Mobility Alloys |

|

|||||

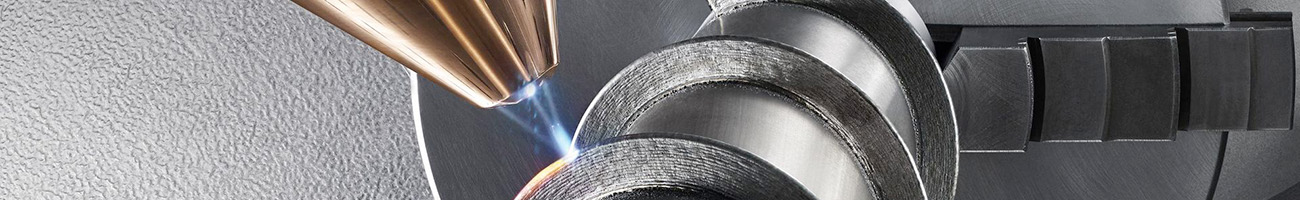

| TT.VI.A.3 | Daniele GROSSO - CV Prima Additive, Turin Rapid coating of brake discs: lase cladding that enables sustainability |

|

|||||

| TT.VI.A.4 | Sergio GALVAGNO - CV ENEA Production of additive manufacturing powders by thermal plasma |

|

|||||

| TT.VI.A.5 | Giuseppe BARBIERI - CV ENEA-CALEF InSPiRATiON: Integrate and Sustainable PRocesses and mAterials for smarT ON demand laser additive manufacturing |

|

|||||

| Back to Fields & Topics | Back to Plan 12 September | ||